|

|

|

|

|

| About |

|

|

|

|

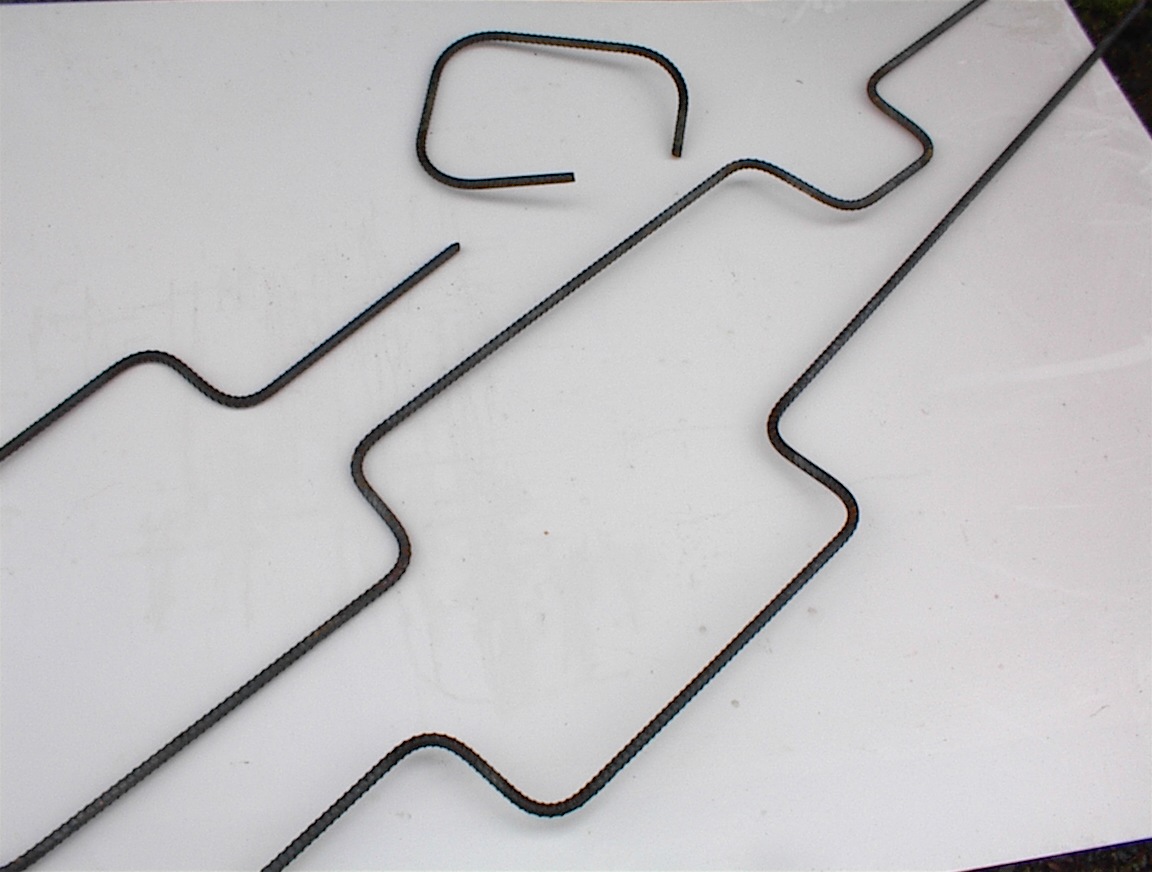

Moss Machine & Tool In April of 2000 Moss Machine and Tony Bryan teamed up to develop a machine that Tony invented to save money for the foundation contractors. In his 30 years working in the concrete industry he had worked at every position from being a laborer at 14 years old to owning his own concrete const. co. During those years he and his crew members had to cut and bend rebar by hand. This started his mind working on the idea of a rebar cutter bender that would be portable to work on the job site, yet also be able to withstand the stress of working all day everyday in the larger contractors shop. He worked for many years operating a concrete pump, which anyone in the concrete industry knows you have to be very savvy to be good at that job. Tony figured out how he wanted to engineer the hydraulics to power the cutter bender from working on the concrete pumps. The concrete pumping trucks have a very large boom that is powered by hydraulics. He was fascinated by their power and learned a lot about hydraulics. He designed a pump that could be small enough to be moved around a job site with very little effort, and give you the power that the very large hydraulic units do. His goal was to build a portable cutter bender that would be an asset to the industry. That meant it would have to be fast enough to cut and bend the steel for an average foundation with one man in less than two or three hours, yet be durable enough to last a contractors carrier. Tony found Moss Machine, who specialized in close tolerances and had the machinery in place. Together Tony and Bill Moss started going through Tony’s drawings and looking for ways to improve from the stage Tony had it at that time. They would agree on a parts function and dimensions, and then built the parts. In most cases the parts worked ok. Ok wasn’t good enough for either Tony or Bill, so they modified each part by combining creative heat treating techniques with particular types of tool steels until they got to a point that made them believe it was a part that could function for many years. Now it is June 2004 and Tony & Bill have a rebar cutter bender that has a patent in place, and will fill that void in the concrete industry. They named it The Eagle Rodbuster. It is built to last, and they have enough end users who have stated that The Eagle Rodbuster pays for its self over and over. It doesn’t matter if it is a small contractor or a big contractor the machine makes them money. A contractor in Sumner Washington can show you how he saved over $96,000.00 in 2003 using the Eagle Rodbuster. You can see for yourself in the video above. The Eagle Rodbuster will cut and bend at the same time. The Eagle Rodbuster will make as many bends as you would need in a 20 foot bar, allowing the contractor to save time tying splices together. Plus the contractor saves money using less rebar in every foundation. The average user can cut and bend 400 to 500 #4 hook bars per hour. An experienced user can cut and bend over 1000 #4 hook bars per hour. The numbers go down a little for #5 bar, and #6 bar. Although the savings do not go down for #5 and #6 bar, because fabricators charge according to the diameter of the rebar. The average price the contractor pays for each cut is twenty five cents, and twenty five cents for each bend using #4 bar. This equates to saving $200.00 per hour with the average user, and can save a lot more with an experienced user. Not to mention the money saved from using less rebar in every foundation, and making fewer splices in every foundation.

|

|

|

|

|

| Copyright [Year] [Your Company Name LTD]. All rights reserved |